Hydrogen Storage and Production Technology for On-Board Systems

The project started in March 2020. The project consisted of three parts:

Preparation and optimization hydrogen storage system containing high-performance HSMs,

Design and development of lightweight hydrogen storage tanks that can withstand 100-150 bar to store HSMs to replace the current high-pressure hydrogen storage technology,

Test and optimize the performance of the hydrogen storage system which includes HSMs and hydrogen storage tank in laboratory and actual environment, in order to establish production lines and commercialize the product.

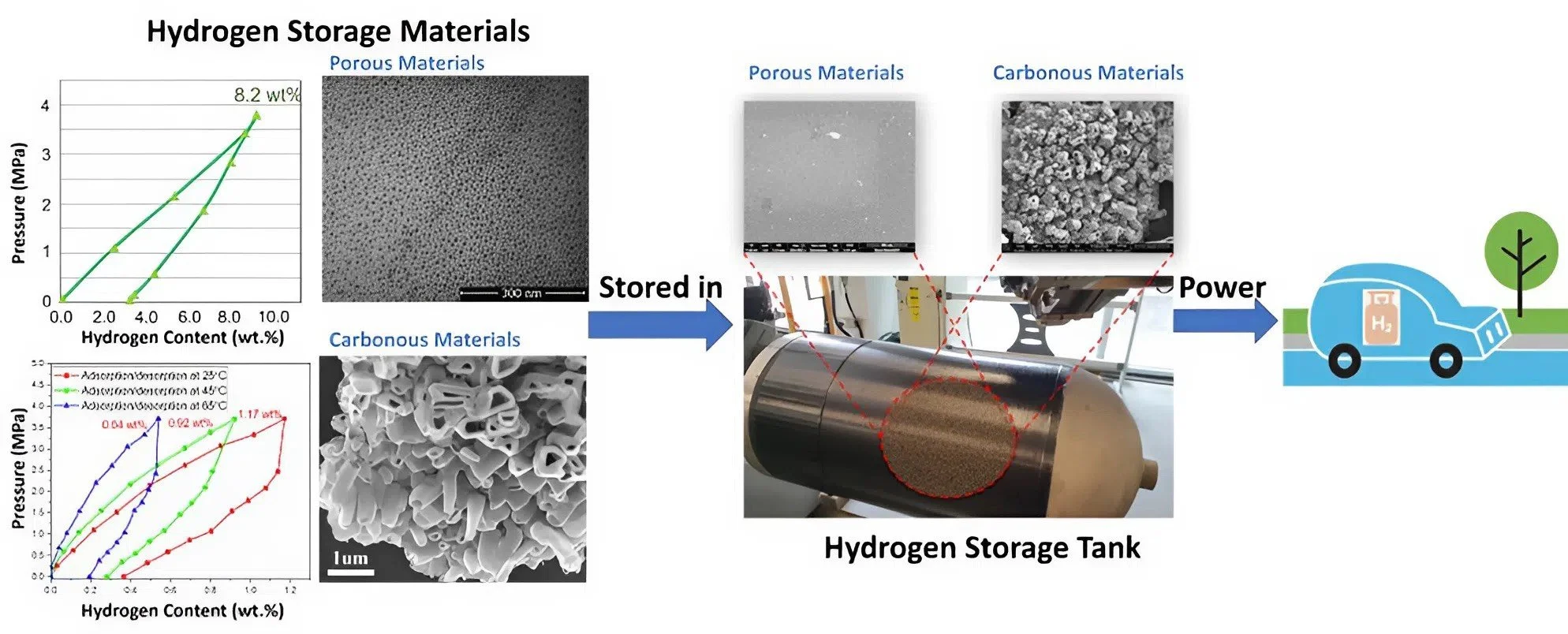

The figure illustrates the hydrogen storage system developed in our group and properties of hydrogen storage materials.

Hydrogen storage system developed in VANIR and properties of hydrogen storage materials

One of the main bottlenecks to realize the hydrogen economy is the effective and safe storage of hydrogen. Current fuel cell vehicles use high-pressure hydrogen storage tanks (700 bar), resulting in high risk, high cost, and high energy consumption. For example, to store 5 Kg of hydrogen in hydrogen fuel cell vehicles (HFCV) to cover a mileage of ~ 500 Km, the cost of each hydrogen storage tank system will be about US$3,000, even under mass production conditions.

Cost-effective hydrogen storage materials for fuel cell vehicles have been developed by our team, which have excellent hydrogen storage performance. The advantages are:

● Fast kinetics - complete storing or releasing hydrogen within 2-5 minutes compared to recharge time in conventional battery-powered vehicles (2-16h).

● The operating temperature is between 20-150 ºC - ideal for the fuel cell and low energy consumption, as compared to magnesium hydride which has a hydrogen release temperature of up to 300 ºC.

● Hydrogen storage pressure is as low as 150 bar, eliminating the use of high pressure (700 bar) hydrogen storage.

● High hydrogen storage capacity (1.17 wt.% for carbonous and 8.2 wt.% for porous materials) resulted from the large surface area of porous structures.

The cost of raw materials is relatively low.

Zero-emission hydrogen fuel cell vehicles (HFCVs) are the future to succeed electric vehicles (EV) for the transportation industry, as they are superior in terms of refuelling time and energy storage. Our project is aligned with the NSW Government's future for using zero-emission vehicles transport and alternative fuels by 2050, as the transport sector is currently the second largest and fastest growing emitter in NSW and Australia. The transition to HFCVs minimizes dependence on imported fuels. Additionally, with the advancement of hydrogen production technology, it is possible to use renewable sources of energy as refilling stations in residential houses.